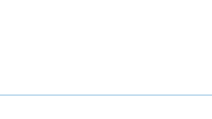

Engineered solutions

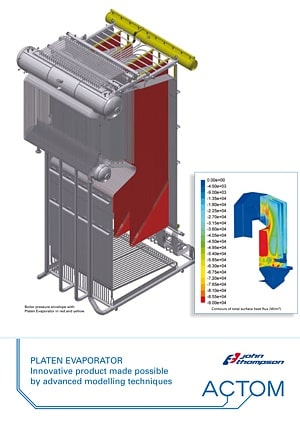

Engineered solutions are made possible with our boiler modelling capability, using various tools such as Computational Fluid Dynamics, circulation modelling and other techniques, unparalleled in the industrial markets that we serve.

This enables us to get the maximum utilisation from existing watertube boilers of all types and sizes, irrespective of the manufacturer. Examples of this include capacity and/or efficiency upgrades for existing plant.

We also offer on-site advice and upgrading solutions to improve plant performance and reduce operating costs.

Services

Design

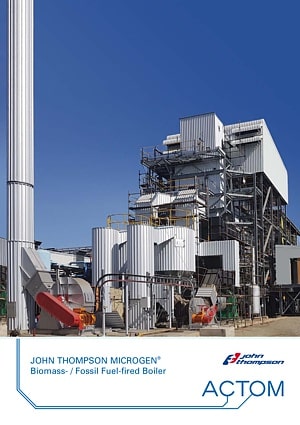

As a leader in the field of boiler technology, John Thompson has always placed a strong emphasis on product development and thermal/combustion technology. Our policy of investing in our engineering resources enables us to lead the field with modern boiler design and more efficient combustion methods.

Our design capabilities include:

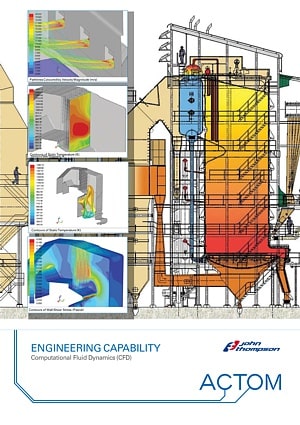

Construction Operations

Our construction department has the teams and equipment to undertake specialist site erection, lifting and rigging services, new installations of piping, vessels and tanks, steelwork erection and specialist welding services for our industrial customers.

Construction services include:

Commissioning Services

After Sales

After-sales services include the preparation of boilers for statutory inspections, re-tubes, burner/stoker repairs, as well as on-site or off-site conversions, including capacity and/or efficiency uprates. Our service teams also provide recommendations regarding maintenance and service contracts for trouble-free running of plant in addition to training and operational optimisation.

Spares

A full range of original equipment spares is available nationwide for all John Thompson and Ical boilers, stokers, mills and other ancillary equipment. A large proportion of cast spares are produced in our own foundry, which is licensed to produce all castings under the Meehanite process. It is the only foundry in South Africa dedicated solely to boiler castings.

Spares include:

Need an old part replaced? We are able to reproduce new parts from old samples with the aid of our in-house design capabilities.