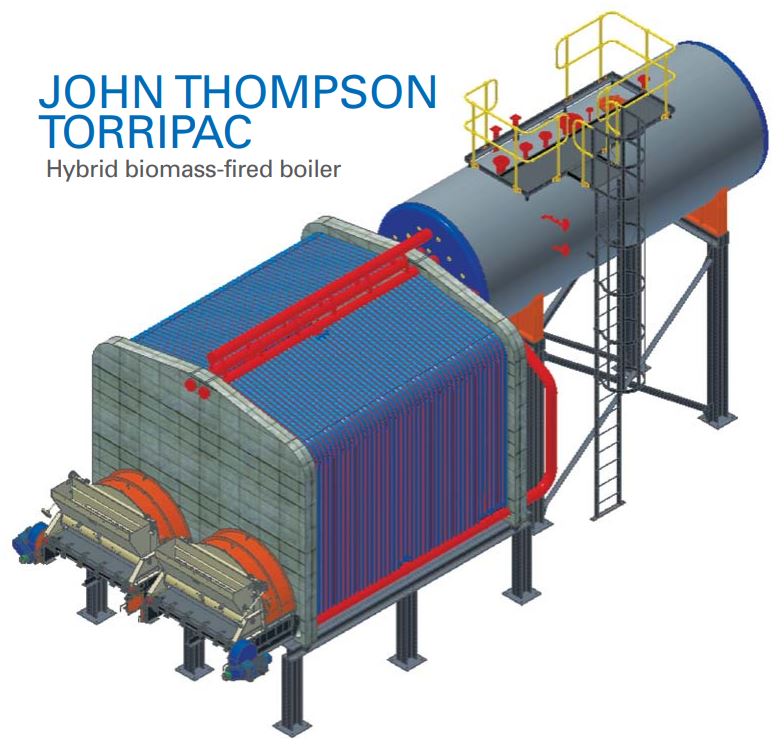

John Thompson, a leading designer and manufacturer of industrial boilers and associated plant, has developed and introduced the Torripac, a uniquely versatile and efficient biomass-fired package boiler.

A hybrid boiler containing some watertube boiler features and a range of enhanced package boiler features, the Torripac has significant advantages over other biomass-fired package boilers on offer. These include:

- It is compact and fully modular, facilitating simple and rapid assembly on site.

- It can handle many types of biomass fuels, including those with high moisture content and high fouling characteristics.

- It has greatly enhanced thermal efficiency compared with other biomass-fired package boilers with refractory furnaces currently on offer.

- The steam it produces is of sufficiently high pressure to generate electrical power as well as process steam.

The Torripac is available in models ranging in capacity from 2 t/h to 16 t/h and delivers steam pressures up to 29 bar and a design pressure of 32 bar.

“The development of the Torripac was driven by the increasing demand of our blue-chip customers to use biomass to generate thermal energy, either by using their own process’s biomass by-product or through purchased biomass in order to reduce their carbon footprint,” commented Simon Boiskin, John Thompson’s Export Sales Manager – Package Boilers.

The boiler uses a vibrating grate combustion system which is considered to be one of the best current methods for burning biomass.

A variety of fuels can be fed into the boiler through its box-ram feeding system, while the vibrating grate combustion system is proven to handle fouling fuels better than traditional methods. In addition, the watertube furnace incorporated in the Torripac is designed to have a low exit combustion gas temperature which further reduces the risk of fouling. A packaged heat recovery tower which includes a two- or three-pass tubular air-heater in combination with an economiser enhances the thermal efficiency of the unit. “The air-heater and economiser extract heat from the combustion gas that would otherwise have exited the chimney unutilised. This heat is used in the air-heater to preheat the combustion air and in the economiser to preheat the feedwater. The air-heater preheats the combustion air sufficiently to successfully dry and combust fuels with up to 50 % moisture,” explained Etienne de Villiers, John Thompson’s Divisional Technical Manager.

The Torripac’s high operating pressure of 29 bar versus the industry standard of 10 bar allows the option of generating electrical power in conjunction with process steam. Power can be generated by passing the high pressure steam through a back pressure power generating unit such as a steam turbine or a screw expander unit. In this way electricity is generated by the high pressure steam while steam is simultaneously reduced to the customer’s required process pressure.

Shortly after introducing the Torripac into the market late last year, John Thompson won a contract to manufacture and supply a 4 t/h Torripac unit for a new rum distillery being built in Grenada in the Caribbean. The fuel in this instance is bagasse, the waste product from sugar cane. However, due to the comparative small size of this operation as opposed to sugar mills, a typical John Thompson watertube boiler would not have been the correct product. The packaged Torripac was a perfect fit for this customer.

John Thompson completed manufacture of the boiler in November 2018 and is scheduled to install and commission it in the distillery during the first half of 2019.

View Torripac biomass-fired boiler advert pdf